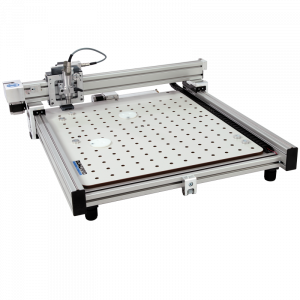

CCD/MTC/XL

|

The Bungard CCD/MTC/XL is a high quality Computer Controlled Drilling and milling machine with semi-automatic tool change (MTC = manual tool change).

The CCD/MTC/XL differs from the CCD/MTC by the larger working area (500 x 600 in contrast to 325x495mm with the MTC).

Compared to the ATC models, the software interrupts the operation during the tool change and the new tool is changed manually (turning the knob by a quarter turn; motors remain empowered and hold the position).

With the sturdy spindle and the good fixation of the tool in the chuck the Bungard CCD/MTC/XL is perfectly fitted for routing or engraving plastics, aluminum and other metals.

The MTC/XL is ideal for extremely large boards and special applications.

Technical Data:

| Power supply: | 110-240 V, 50-60 Hz + vacuum cleaner (1500W) |

| Range of RPM: | 30.000 – 63.000 |

| Traveling speed: | 1 – 9000 mm/min |

| Software resolution: | 0,0001mm (0,1µm) |

| Mechanical resolution: | step resolution: Software selectable: 1 mil, ½ mil, ¼ mil (= 6.35 Mikrometer) |

| Tool diameter: | 0.1mm – 3,175mm (recommended, bigger tool diameter possible) |

| Position accuracy: | 20 ppm (0.002%) over the entire work space: |

| Maximum position speed per axis: | 9000/mm/min (=150 mm/s) |

| Maximum working speed per axis: | 9000/mm/min (=150 mm/s), individual setting on a per-tool basis, independent from position speed |

| Drill speed: | 5/s (= 18.000 holes/h= 300 holes/min) |

| Required Accessories: | Computer |

| Board fixation: | span fixing, clamp fixing, reference pin system, stack processing possible Option: vacuum fixation |

| CCD/MTC/XL | |

| Weight kg | 49 |

| Dimension mm | 950x950x300 |

| Work area mm | 500x600x38 |

| Tool change | no |