Comfortline Level 3

System features:

- CCD/ATC for enhanced drilling, COMPACTA 30 2 CU doubles galvanic throughput, a second laminator RLM 419p avoids changing rolls between the steps!

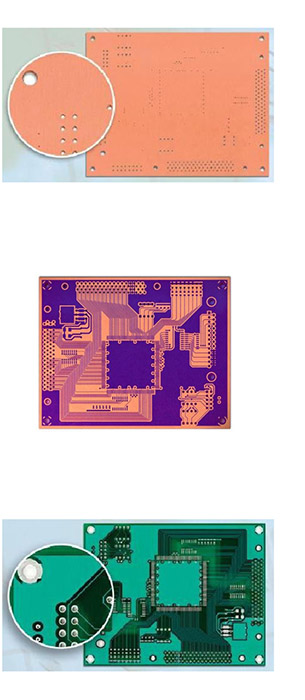

- Fine-line technology in industrial quality with green solder mask and blue components printing!

- (To make components printing repeat again from laminating but with RLM 419p #1 and blue tenting resist)

- Modular upgradeable to multilayer, artwork production, waste water treatment or surface finishing set at any time !

- Track resolution: better 150µm!

- Film production with laser printer or bubble jet or local film supplier.

- Processing time: approx. 2 hours

- maximum throughput: 2,0m² / 8h – more than twice the volume of Basisline 3!

- maximum usable size: 210 x 300 mm